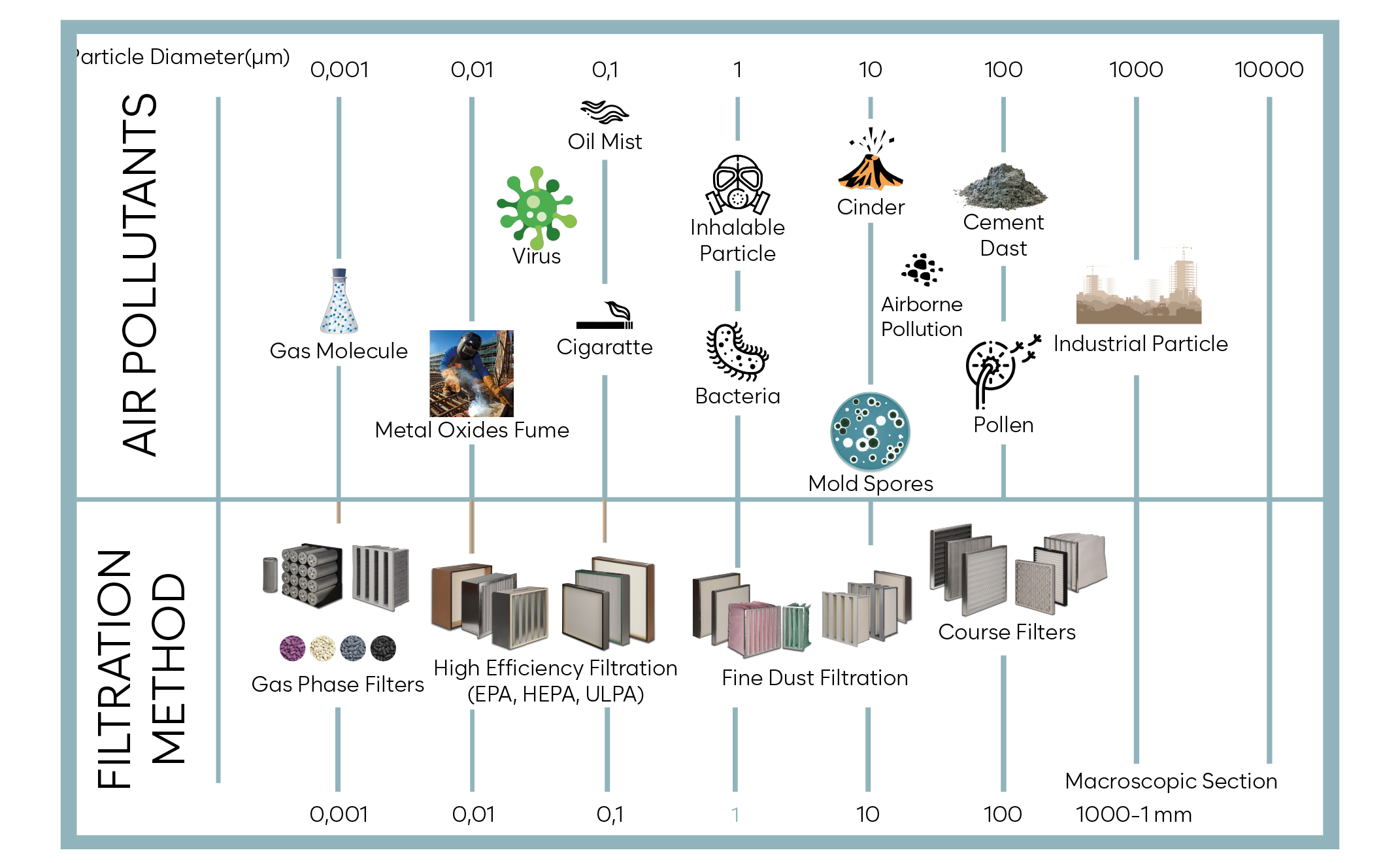

Airborne pollution sources are various which can be from natural sources like volcanos, thermal sources, pollens, sand storms and from industrial life like factories, automobile emissions, jet fuels, garbage dumps ete. Pollutants are divided in to three physical conditions as solids, liquids and gases. Effective pollution control can be easily made by particulate and gas phase filtration. These filtration methods and applications are define at ISO16890, EN1822, ISO 10121-3. Airborne pollutants comparison chart shows size differences related particulate and gas phase filtration.

In order to apply the control methods for the gas phase pollutants, we have to know the pollutants and it’s effects. Main airborne pollution effects;

Corrosion Control

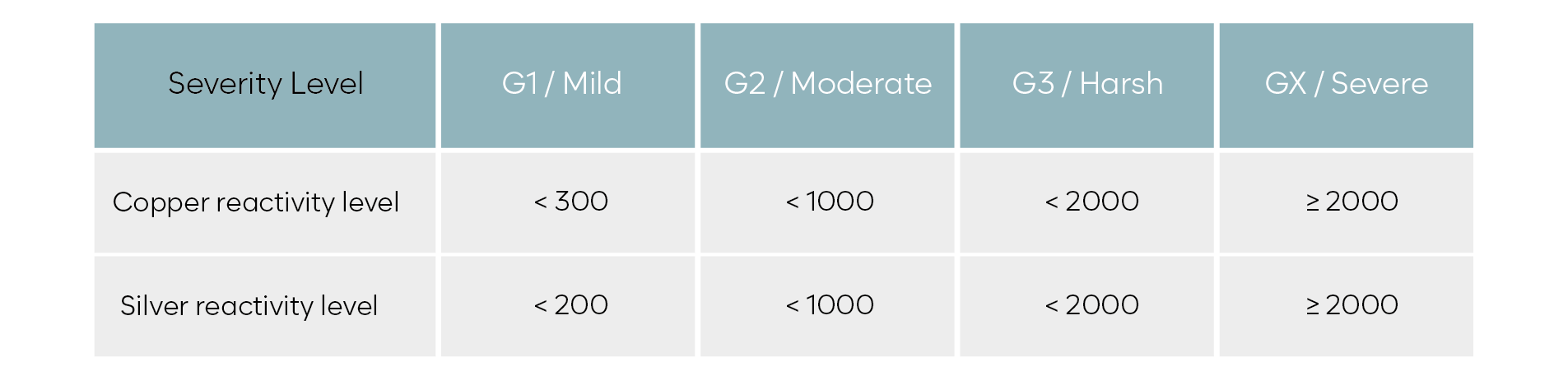

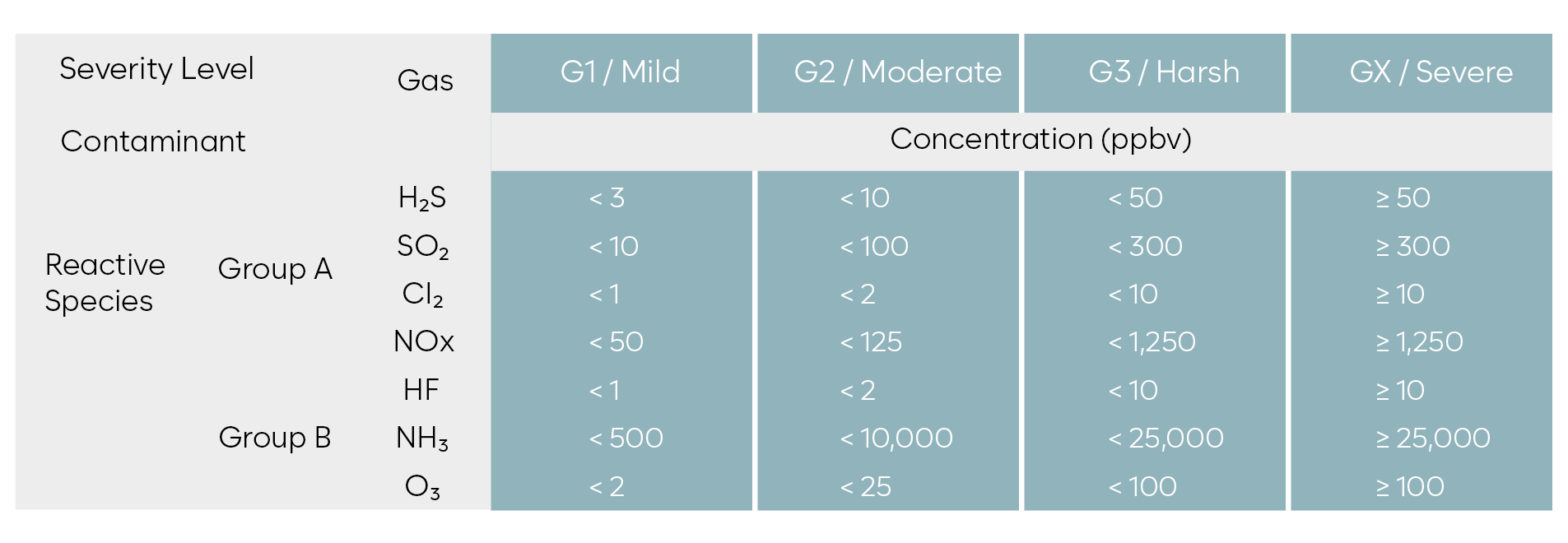

Process control systems, data centers and other rooms that have instrumentation which has to be environmental controlled must supply Gl classification according to ISA requirements. Achieving room ventilation design requirement must supply a minimum room pressurization of 1-3 air changes per hour and recirculationof 6-12 air changes per hour. Temperature is typically 22°C (±2°C) with humidity lower than 50% relative humidity. Tightness of the room is also another parameter while defining the design parameters. In addition to these parameters, hazardous pollutants are main parameter which must be removed from the enclosed space, According to the ANSI/ISA 71,04, contamination concentration levels are defined as follows.

Monitoring for gas phase air filters is made by passive monitoring or online monitoring.

Passive Monitoring: It is made with copper-silver coupons which must be used at the site with

30-90 days periods for defining remaining life and design parameters.

Online Monitoring: It has an instant measurement of gas contamination.

Particulate Filters Monitoring: Differential pressure gages are used for filter life monitoring.

Odour & Toxic Gas Control

Odours are generally formed from commercial and industrial facilities like biogas, waste water treatment plants, etc.

Toxic gas scrubbing is generally needed for filtration and neutralizing of chlorine(CIJ, sulfur dioxide(SO,) or ammonia(NH₃).

Biogas Plant

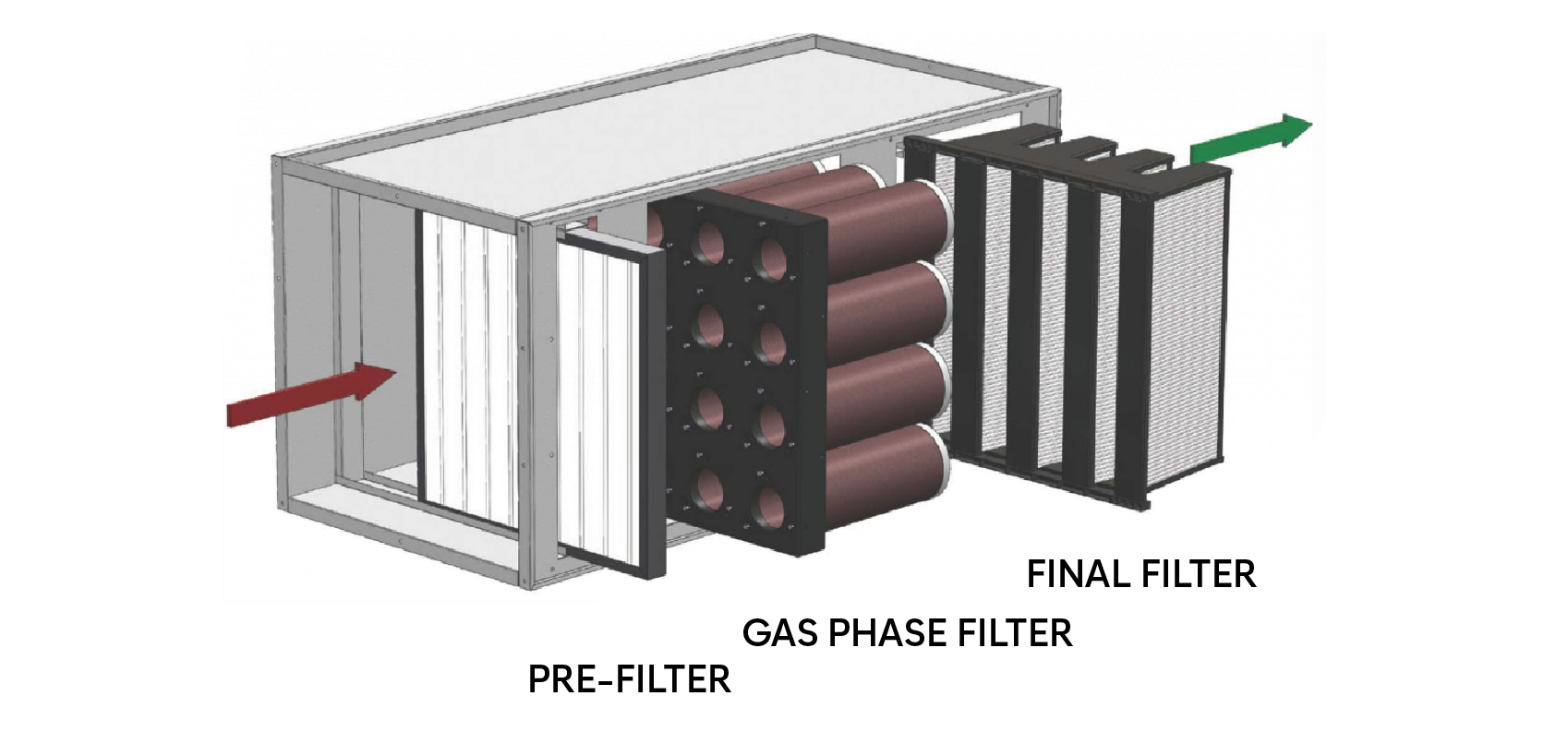

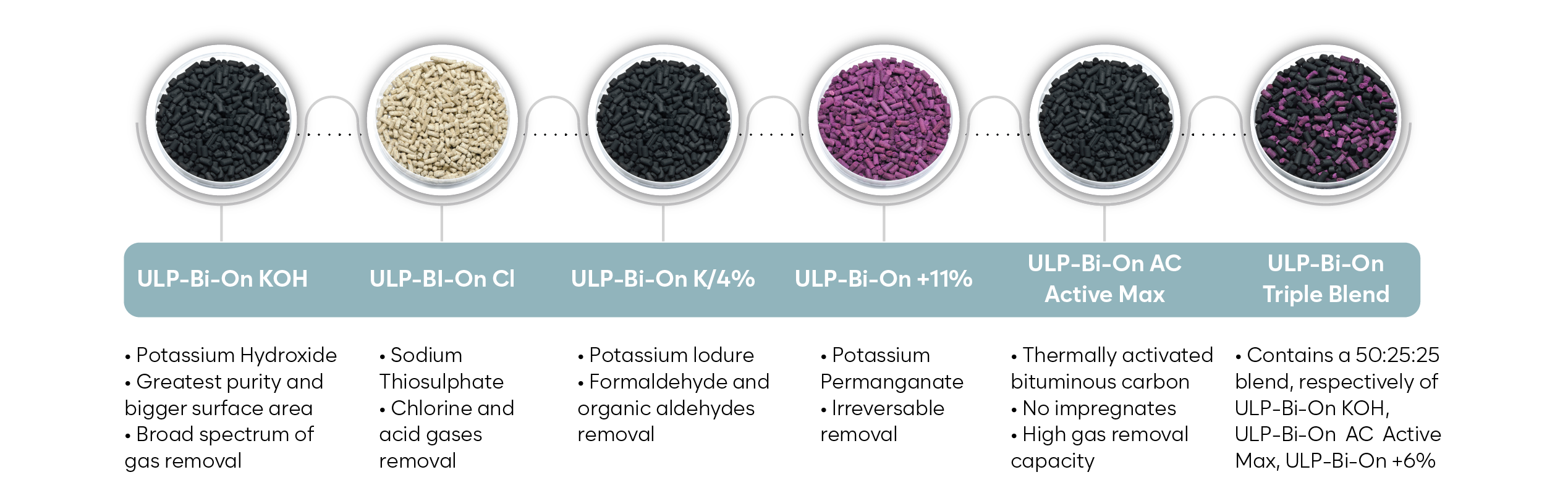

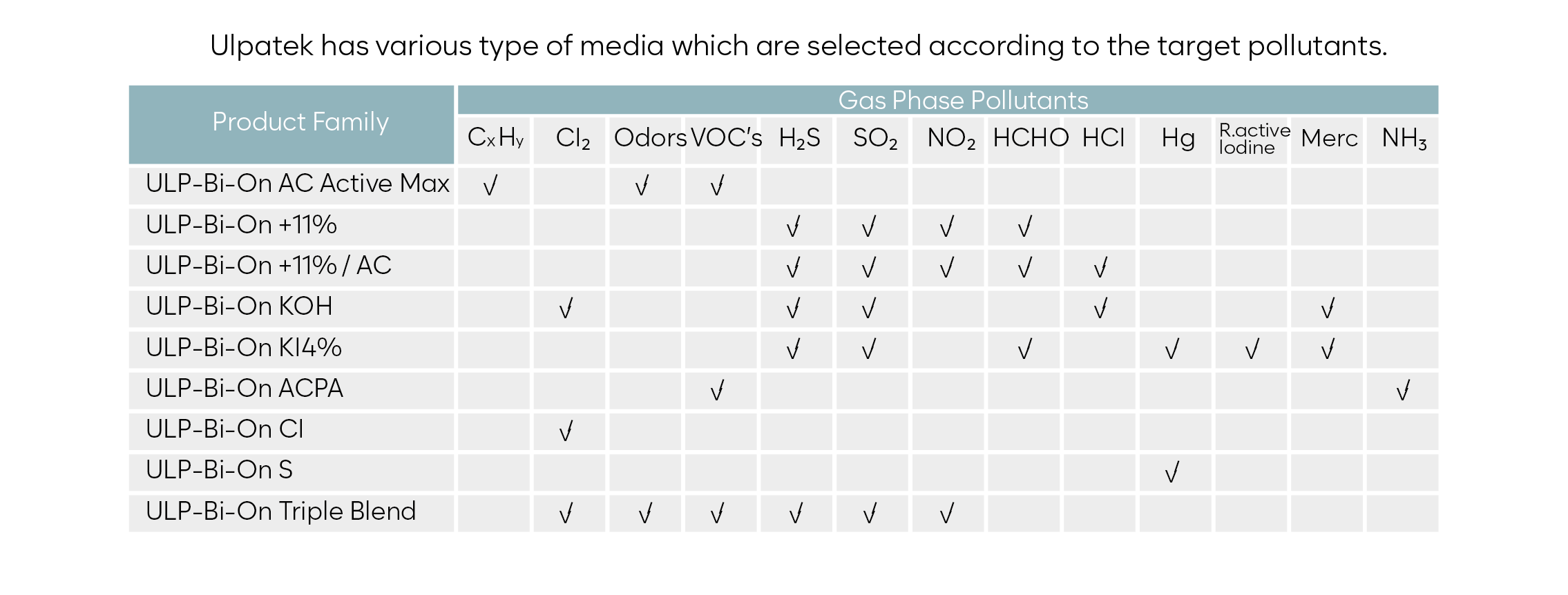

Gas phase filtration and particulate filtration work together for acceptable indoor air quality in controlled environments. Gas pollutants are filtered with Ulpatek’s gas phase air filters which are produced from one or mix filter media. Particulate pollutants are controlled with particulate filters which are mentioned in related standards as course, fine and high efficiency filters. Gas phase filter media (pellets) generally are produced using carbon, zeolite, alumina or coconut-based media. Gas phase filtration occurs with the two different methods which are physical and chemical.