CEN standards in Europe, IEST and MIL standards in the US are used for HEPA and ULPA filters. HEPA / ULPA filters are individually tested and certified in accordance with both standards in Ulpatek.

HUF-SCAN 4002

HF-SCAN 3004

HF-OIL MIST 1200

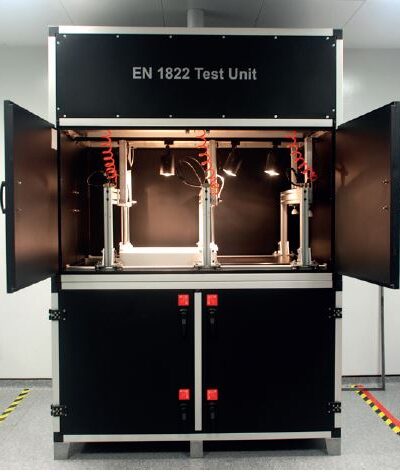

In the system, the filter surface is scanned at nominal air velocity by automatic probe which counts particles at MPPS by connecting particle counters counters are connected at MPPS and nominal air flow rates.

• Aerosol concentration is counted by the particle counters before and after the filter during test.

• It is a test method in which the lowest penetration value which is accepted according to the filter class is checked in Class 100. If there is a leak, it detects the leakage points and print as a figure.

• Scanning test is the most advanced filter efficiency test used to test HEPA and ULPA filters.

Test operator scans the filter surface with the probe which is connected to photometer to check the leakage at 0,3 μm particle size. Test is applied for

each filter individually.

• In the leak tests of HEPA filters performed at the nominal air flow rate, aerosols such as Emery 3004, PAO etc. are used according to standard.

• The high concentration of aerosol fed during the test is checked in the Class 100 test area by scanning the filter surface and sealing surface with the probe to check leakage.

• If there is leakage, repairing can be carried out by applying special adhesive according to the standard and customer requirements to the leakage point.

• After installation of the filters in the field, performing this test is recommended before commissioning system.

Oil Thread Leak Test is done by naked eye for checking leakage on the HEPA filter surface at a nominal air flow rate using DEHS as aerosol.

• The particles formed as oil smoke lines from their leak points can be easily seen with the black colored cabin interior design and the appropriate light angle.

• If there is leakage, repairing can be carried out by applying special adhesive according to the standard and customer requirements to the leakage point.

• Used as an alternative leak test method for class H13 and H14 class filters.

• It provides easy testing for filters which are not suitable for the scanning test (V-Compact, cylinder filter, filters without faceguard protection).